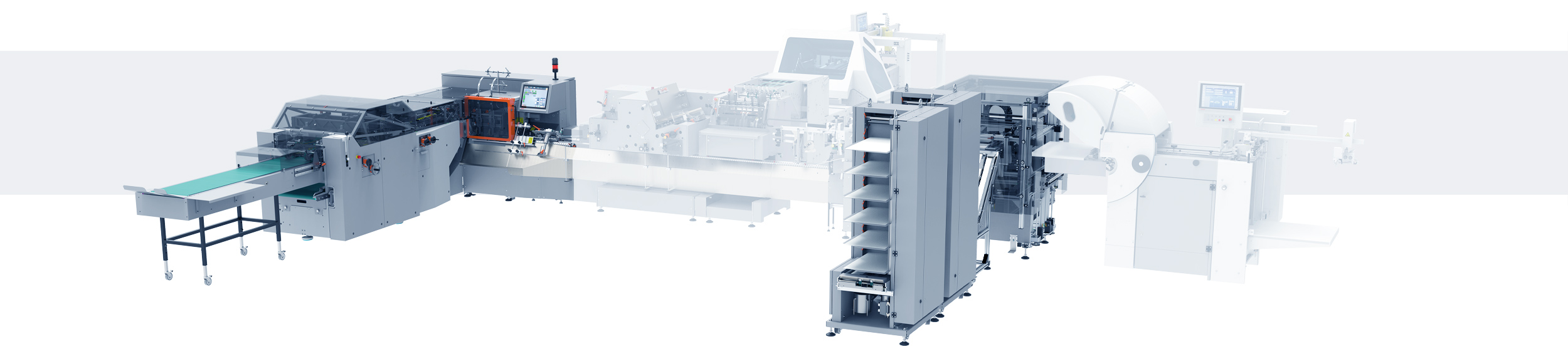

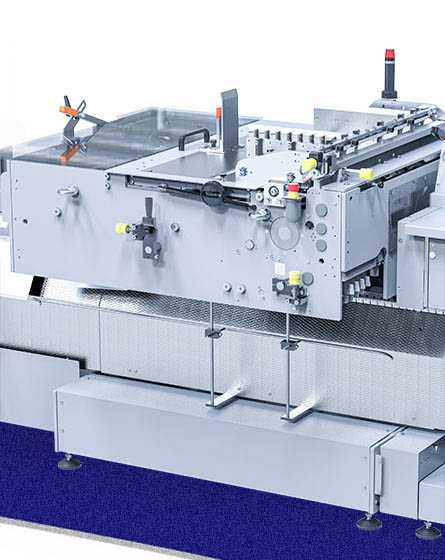

This ultimate concept with up to five feeding functions that grows with your needs and flexibility thanks to its modularity - in terms of technology, quantity and versatility. Complete freedom to choose the point of time of a possible extension of the many combination possibilities arising out of the five components and the base unit. The modular concept of the FUTURA allows a very individual configuration fitted to your needs. More than 20 different configurations are available; some of them even offer parallel production mode.

Sascha Schmidt

Do you have questions or need more information? Please contact our sales department.

T +49 7462 9468-888

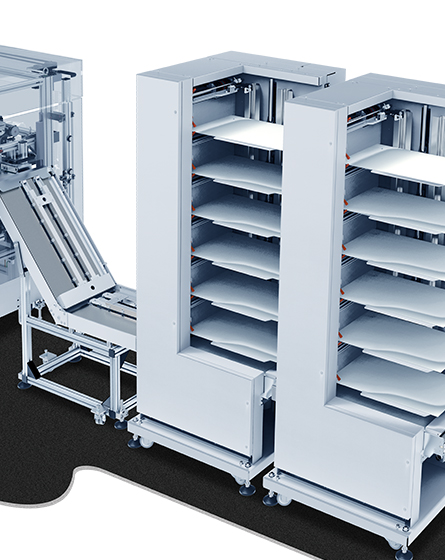

The modular and flexible concept of the HHS-FUTURA 9 also includes the Hohner designed collating towers and a 90° delivery for the inline collating function. Space saving, compact and suitable for a non-stop production. With this Hohner component the FUTURA becomes the most versatile concept in saddle stitching. The Towers with six paper bins can be combined with the KDAL (compact-digital-feeder). Covers can be fed either from the tower or from the cover feeder; the feeding from the cover feeder implicates the two advantages of a better folding quality and a higher production speed. The collating towers can convert a minimum format of 148 mm x 210 mm and a maximum format of 364 mm x 610 mm (min. and max. width and length cannot be combined); a landscape format of 267 mm x 610 mm is possible also. The according 90° delivery grants a smooth delivery to the scoring and folding unit.

(To combine the collating towers with the digital finishing components within the same configuration, the 90° delivery will shortly be available with automatically adjustable by-pass option too.)

Collating Tower

Nonstopproduction inclusive - In the modular and flexible concept FUTURA also includes with this new solid Hohner designed tower, the inline collating function and offers customers the chance to choose an adapted non-stop production if needed. Space saving and compact for a wide range of paper weight. With this new inline collating component of proven solid Hohner engineering, the versatility grows further and makes the machine a long term flexible concept well into the future. With an infeed width of 364 mm and a sheet length of 610 mm, the machine can handle a small format of 160 x 120 mm and a landscape format of 267 x 610 mm. The tower is offered with 6 – 8 and 10 paper bin and is designed for a wide range of paper weights for both the content and the cover. Moreover, the 90° delivery of Hohner engineering grants a smooth feeding straight on the collating chain. Depending on the desired converting mode the 90° delivery fulfils a real double function; it can stitch from 90° delivery mode to a simple by-pass function when being used in combination with another feeding component. Thus, the digital application from whether print roll or sheet feeding. This new collating tower now offers customers the chance to choose an adapted non-stop production if needed. Completed by this space saving compact feeding alternative the machine hardly has any limits.

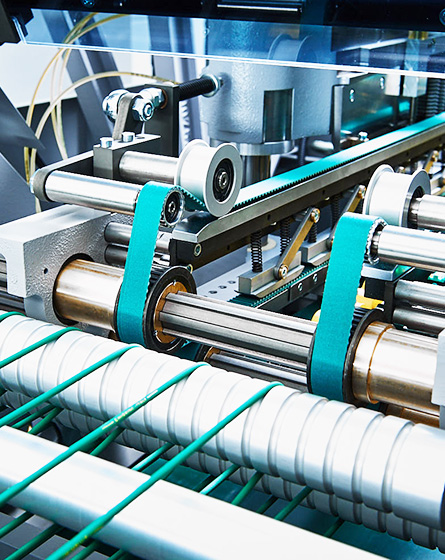

Scoring and folding unit

With a separate servo drive and a positive negative adjustability without any tools. The fold stitching module plus scoring unit allows production inline through folding plates of the integrated fold machine. Within the same process, folding and delivering the signatures straight on the collating chain happens. In combination with the collating tower, an alternative component, the scoring and folding unit within the Hohner puzzle can become a multifunctional part of the line.

Option: Cover feeder

Our cover feeder further demonstrates the modular nature of the HSB 9.000. This ergonomically designed cover feeder works vertically. It can be loaded with more sheets than horizontal cover feeders; ideal surface protection is guaranteed and feeding runs very smoothly to the inner or outer scoring station for an accurate folding of the cover. Stripes and marks are no longer an issue. The cover folder is leader in its class with a maximum format of 640 x 360 mm (unfolded x spine length). Two pairs of grippers at the feeder drum reduce feeder speed and protect the machine as well as the sheet; an adjustment and maintenance free signature inspection unit with photocell is also standard. The folding and scoring element of the HSB 9.000 is also equipped with a double sheet control and an electronic on/off switch option for the vacuum. Just as with the vertical feeder the drop time of the sheet to the chain can be individually adjusted. The format setting is also toolless in this case for all detailed adjustments, for example setting format, centralization of the complete stack, fine setting of squareness of the score, switching from inner to outer score and vice versa, fine setting of the score pressure, finally adjustment of fold roller pressure.

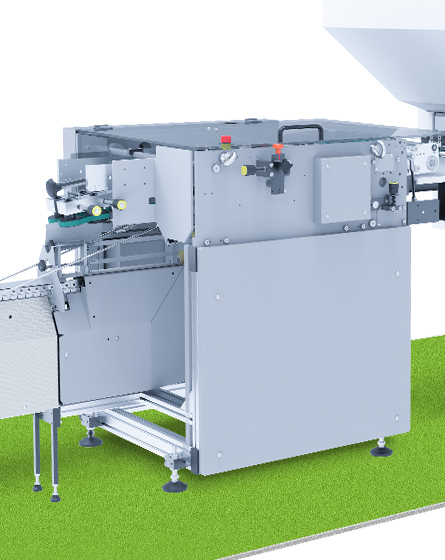

Option: PAL Flat Pile Feeder/Cover Feeder (horizontal)

This compact cover feeder operates from flat pile and can process lower grammages than the vertical cover feeder (UAL). It is the perfect combination to the vertical cover feeder (UAL).

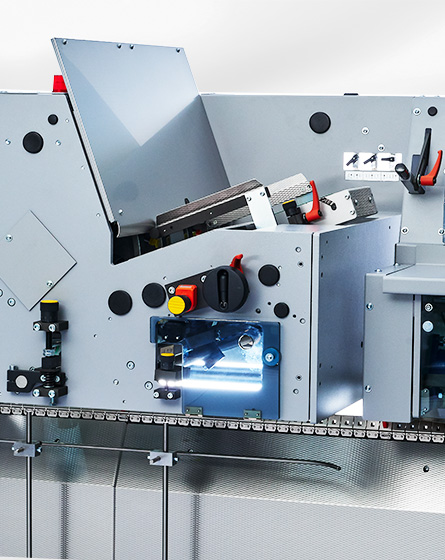

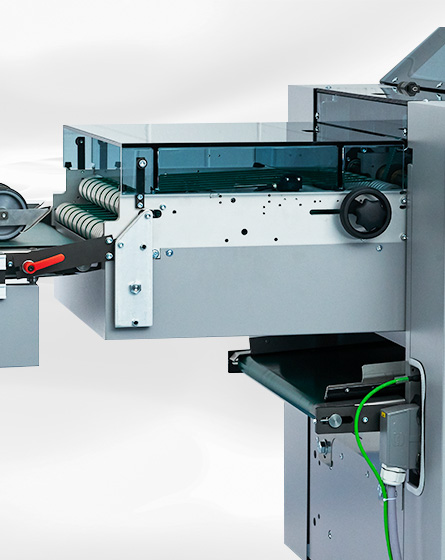

Touch Screen

This intelligent electronic control system makes all HSB 9.000 processes run smoothly. For example, the programmable logic controller (PLC) enables infinitely variable speed control in real time (~1,000–9,000 cycles/hour). Individual feeders are switched on and off manually. Thickness monitoring, as well as missing-sheet detection, is centrally controlled and monitored. Furthermore, the PLC controls the synchronous filling and emptying of the collecting chain (cascade connection) as well as the total and partial total counter with shingle marking. Error messages in the event of paper jams, missing sheets, unsealed protective covers, etc., are indicated optically via a signal lamp and additionally as image and text information on the display. The generous 15'' touch display is ergonomic and modern, providing an immediate overview of the relevant machine settings and information. Even error messages down to the sensor level are visualized, helping you to find simple and immediate solutions in the event of a fault. This is intelligence that saves time!

Stitching unit

It is a proven fact that you buy experience when you choose any of our stitching heads. Once you combine them with the stitching unit of the HSB 9.000 there are many advantages for the user. The stitching unit is equipped with 2 Hohner Universal 52/8S narrow stitching heads as standard, this can also be extended to a maximum of 4 of these extremely operator friendly stitching heads. With the Universal 52/8S we have decided on the fast all-rounder from the Hohner-Narrow Stitching Head series. This head can easily handle 9.000 stitches per hour. The precise central adjustment tool of the HSB 9.000 grants an efficient adjustment of wire length and stitching thickness at the same time. A new developed stitching monitor system (without any mechnical setting) as well as a caliper control are available for optional integration, allowing by this the maximum quality control without increasing the length of the line. There is a choice of many optional exchange part sets to offer the use of various crown widths, loop diameters, and wire types. The stitching unit itself is a completely new design. The reliable gripper system (transport finger with polyurethane inlets) ensures exact positioning of staples in brochures even at maximum speed. Flexibility, speed and precision – all in your favor.

Trimmer

All relevant settings for a perfect three sided cut are easily adjusted by hand without the need for tools in a matter of minutes. Even two-up production (optional) can be adjusted in only minutes. Innovative gear box technology allows gentle braking of the belts, so that even products travelling at higher speed are slowed down gently as they arrive at the backstops. Quiet running and cutting accuracy characterize this trimmer. The knives are combined in a yoke and are guided by six lineal bearings. This results in a totally accurate guide system which does not allow any movement, ensuring an extremely long life of the blades. For optimum protection of the surface of the product, the transportation belts come to a complete standstill during the cutting process. Quality - a Hohner strength.

Conveyer table

Hohner offers the right conveyer table for all applications. Connecting other units, including units from other manufacturers or Hohner delivery devices such as compensating stackers or shingle conveyors, are connected here.

Shingle delivery

The Hohner shingle delivery will automatically batch products on the delivery belt. An optional offset conveyer allows more time to bundle, as it alternates batches either side of the delivery belt. This gives you more order and easy recognition during production. Thinking for the customer – another Hohner quality.

Compensating stacker

It combines simple and rugged design with convincing performance values with automatic control and time-saving ease of operation.