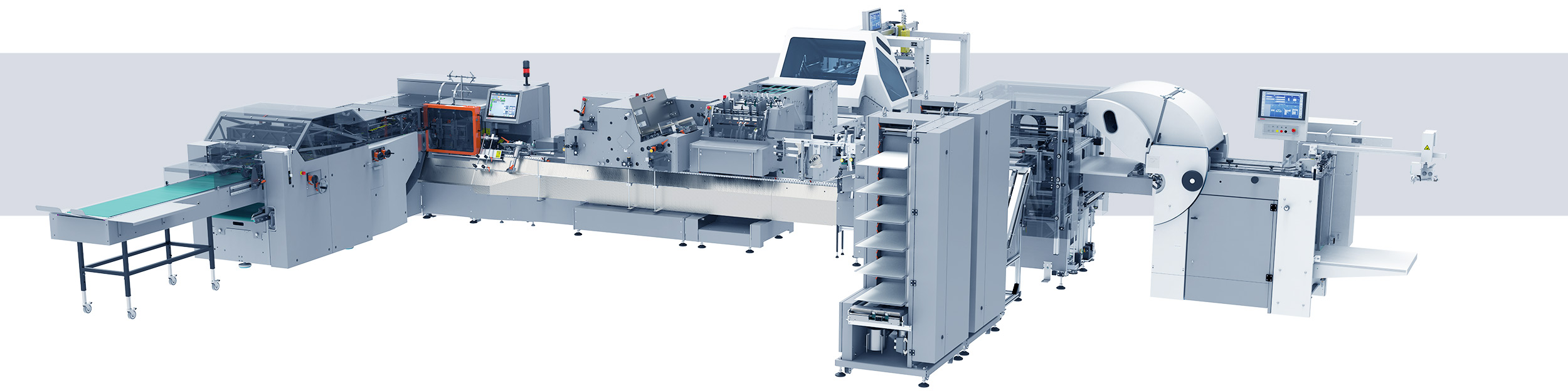

This ultimate concept with up to five feeding functions that grows with your needs and flexibility thanks to its modularity - in terms of technology, quantity and versatility. Complete freedom to choose the point of time of a possible extension of the many combination possibilities arising out of the five components and the base unit. The modular concept of the FUTURA allows a very individual configuration fitted to your needs. More than 20 different configurations are available; some of them even offer parallel production mode.

Sascha Schmidt

Do you have questions or need more information? Please contact our sales department.

T +49 7462 9468-888

Given our expertise of saddle stitching and being the market leader in stitching heads, it’s no surprise we recognize the market’s needs. A combination of experience with our hybrid saddle stitcher models DIGI-Finisher and DIGI-FS9, along with the growing list of customer needs, led to the HHS-FUTURA 9. A machine concept that offers unrestricted expandable configuration possibilities for the long run, while also taking into account the trend of smaller runs with continuously increasing variety and more individualized products. You cannot change the wind but you can adjust the sails, and the HHS-FUTURA 9 allows exactly just that, thanks to infinite freedom with the modular configuration of five different feeding systems capable to be connected with an open concept. That’s one of a kind.

In addition to the winning argument of flexibility for the long run, the FUTURA includes advantages to improve efficiency. Depending on the level of configuration, the concept also delivers potential for savings compared to the competitor’s alternatives. The FUTURA can provide reduced energy cost, less environmental emission, as well as less space and less operators. According to the chosen expansion phase of combinations, the FUTURA has the capability of doing the job of which would normally require at least two separate machines. All of this goes along with a clear and manageable investment cost.

A solid base for the FUTURA - A stitching unit with automated wire length and thickness adjustment including stitching leg via a 15 inch color touchscreen with intuitive and non-text design and a trimmer allowing a format up to B4 final format with optimum trimming quality. Extremely user friendly! The proven Hohner stitching unit and the trimmer are building the core of the HHS-FUTURA 9. Stitching thickness of up to 5 mm and – in the spirit of maximum ease of use – a reverse mode at the trimmer are our standard. Relying on these solid core components, the FUTURA can include up to five different alternatives and combinable feeding systems, all modular and expandable.

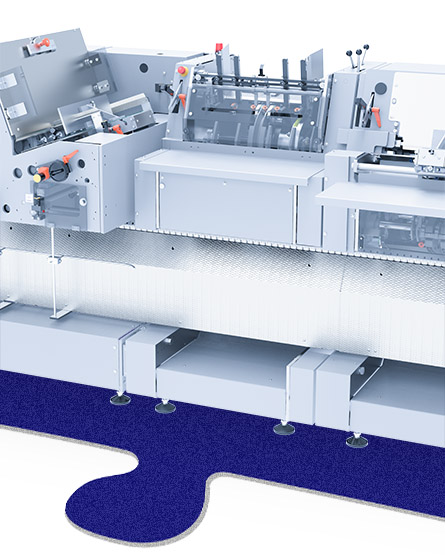

Infinite modularity - The shown configuration reflects a compact minimal version, which of course can easily be converted to a fully equipped saddle sticher version according to the possibilities of the former HSB 9.000, Hohner’s tool-less saddle stitcher. Four different feeders to freely choose from and combine: Cover Feeder, Horizontal Feeder, Vertical Feeder and Compact Plano Sheet Feeder.

FUTURA shines with versatility. Our KDAL is available for the most compact solution and thanks to its loading method it offers the advantage of a non-stop production run. Of course, the components

of our Postpress Alliance Partner MBO Postpress Solutions can be used as well. Either the unwinder UW23 for roll diameters of up to 52“ + cross cutter SCV525C or the buckle plate folding system T50 with the latest control generation M1 are available. In short, the FUTURA can become the perfect DIGI-Finisher in three different ways, according to the customer‘s preference. Nothing stands in the way of later integrating the digital finishing variants as well as the integration of an existing component. The selection of another manufacturer of these types of components - provided open interfaces - is also possible at any time.

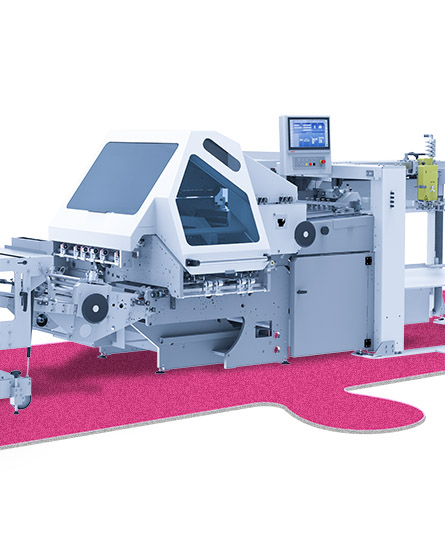

The component for folding and scoring - Extremely time saving thanks to the integrated pre-process of folding) for a sheet length of up to 1300 mm and a width of 520 mm (in optional version even up to 660 mm)*. Scoring and folding unit with a separate servo drive and a positive negative adjustability without any tools. The fold stitching module plus scoring unit allows production inline through folding plates of the integrated fold machine. Within the same process, folding and delivering the signatures straight on the collating chain happens. In combination with the collating tower, an alternative component, the scoring and folding unit within the Hohner puzzle can become a multifunctional part of the line. ( * depending on manufacturer)

The K70 of MBO Postpress Solutions allows high-precision and high-performance production of folded products for medium and high print run lengths in a B1 format (70 x 100 cm) with direct delivery to a horizontal signature feeder. The crossfolding mode, in the current layout offered by MBO Postpress Solutions with the K70 , widens the capability range of the HHS-FUTURA 9 to folded products by a fold in a B1 format / 70 x 100 cm like signatures and flyers for medium and high print run lengths – solving even the most complicated folding impositions. Integration of more than one crossfolding unit is possible.

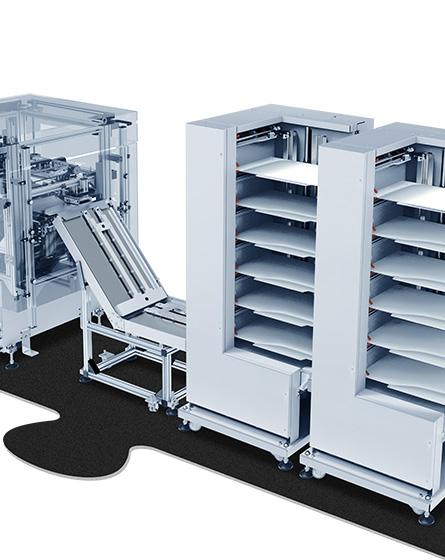

Nonstop-Production inclusive - The modular and flexible concept of the HHS-FUTURA 9 also includes the Hohner designed collating towers and a 90° delivery for the inline collating function. Space saving, compact and suitable for a non-stop production. With this Hohner component the FUTURA becomes the most versatile concept in saddle stitching. The Towers with six paper bins can be combined with the KDAL (compact-digital-feeder). Covers can be fed either from the tower or from the cover feeder; the feeding from the cover feeder implicates the two advantages of a better folding quality and a higher production speed. The collating towers can convert a minimum format of 148 mm x 210 mm and a maximum format of 364 mm x 610 mm (min. and max. width and length cannot be combined); a landscape format of 267 mm x 610 mm is possible also. The according 90° delivery grants a smooth delivery to the scoring and folding unit. (To combine the collating towers with the digital finishing components within the same configuration, the 90° delivery

will shortly be available with automatically adjustable by-pass option too.)