Eduard Martin,

Schwabenprint Industrial Printing Company LLC, Virgina/USA

|

CEO

... The proximity of their operations, coupled with direct communication and expert guidance tailored to our requirements in roll-fed digital finishing, facilitated a swift implementation. Not only did the HHS-Futura impress us with its robust design, but its excellent ergonomics and easy accessibility further exceeded our expectations. The chosen configuration, incorporating MBO components, not only maintained efficiency but also allowed for a reduction in speed while sustaining the same number of cycles. The seamless process, from installation to training and after-sales service, reflects perfection in every aspect. The knowledge and dedication demonstrated by Hohner's motivated team played a pivotal role in ensuring our timely commencement of operations."

Hervé Lesseur,

TagG Informatique

|

CEO

... Forget the mass campaigns with several hundred thousand recipients but also the waves of e-mailings - certainly quite economic but often with the riskiest fallout. We are now entering a period of maturation where each technique naturally finds its place. Thus, today, at TagG we print and customize starting from the blank sheet with total variability, it is the CMYK customization. To go even further, by using the know-how of our internal Research and Development team, we developed Ultraflex: The customization that allows the adaptation to your requirements: format, paper, content, images... for truly unique messages. At TagG, more than ever, innovation and creativity dictate our daily lives. The decision to choose the new Hohner HHS-FUTURA Hybrid Finisher, which will be installed in spring 2022, is perfectly in line with our philosophy. In addition, Hohner's experience in the world of industrial saddle stitching, the robustness of the equipment, the ease of its use and the way in which it can adapt to the different needs of the market have enhanced our choice significantly."

Takashi Yanagawa,

FFGS/Fuji Film

|

... Hohner perfectly fits in our strategy and product portfolio as they demonstrate a great flexibility and willingness to adapt and customize machines to our needs. We have immediately noticed the very high technology behind their engineering and have considered Hohner saddle stitchers and DIGI-Finishers to be attractive for us and the Japanese market. The partnership with Hohner works well, because they are really interested to understand the particular requirements of our market. In terms of Management the shows the right personality; but really, the whole team proves flexibility and speed on demand with a serious attitude of continuous improvement. We look forward to growing this partnership further to a successful business in Japan for a long future in our mutual interest."

Bo Zhu,

Zhejiang Lanbao Machinery Co.,Ltd

|

Managing Director

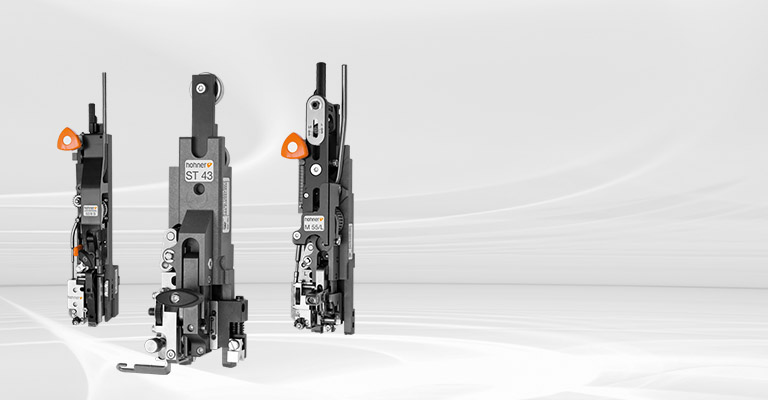

... about the higher price level of the Hohner stitching heads. So we have followed the smart proposal of Hohner Nanjing to go for a test phase with Hohner heads at one of our final customers with the result that all of us have been convinced of the extraordinary quality of Hohner’s stitching heads; with 10 stitching heads per machine it’s evident that a defect head causes a production stop each time, which means a high cost for our customers. In the meantime we equip all our machines with hundreds of the reliable Hohner stitching heads 43/6 and 52/8 per year and in this way help our customers to save money. Hohner to us means definitely quality that pays off.“

Zhenmin Dong,

Tianjin Shiwei

|

Plant manager

... which should match our expectations towards speed, product variety, flexibility and fast customer service and granting next to that the highest technological reliability. The DIGI-Finisher fulfils all that; it has been the perfect decision for us; the fact of having right a year later another second line of the same type, is probably the best proof.“