Mike Kingery,

Kingery Printing Company | Illinois, USA

|

CEO/Owner

... The transaction, installation, and training went like clockwork. In any equipment deal, the difference comes down to the people behind the machine—and the Hohner team was exceptional to work with. The machine and its features have met and exceeded every expectation. Kingery operators are very pleased with its reliability and ease of operation.“

Manuel Martos,

Merico, Groupe Paragon | France

|

Production Director

... and fully understand our technical needs, as well as our high expectations regarding the quality of the finished product. As we operate in markets where quality takes precedence over quantity, it was essential for us to replace our existing, outdated saddle stitcher. Hohner enabled a comprehensive evaluation by organizing visits to several printing sites in France, Germany, and Spain, which proved to be a decisive factor in our purchasing decision. Our production includes highly complex jobs, such as double-up production and very small formats with two staples each. To meet these challenges, Hohner’s engineers presented a tailored solution featuring narrow special stitching heads, tested under real production conditions. Our operators were impressed by the excellent cutting quality, the complete absence of marking, and the simple, intuitive operation of the machine. Despite manual settings, the machine is ready for production in less than ten minutes, completely tool-free and without any rework, which is an obvious advantage in daily operations. In addition to the double-up option, we also selected single hole punch device for calendar production, loop stitching heads, and a cross stacker. Installation, commissioning, and operator training were carried out smoothly and professionally. Hohner’s after-sales service is exemplary, with very few interventions, fast response times, and precise problem resolution. Thanks to the technicians’ extensive machine expertise, many requests can be resolved by phone or via the remote maintenance system, which allows a direct connection to the Hohner factory in Germany when required."

Eduard Martin,

Schwabenprint Industrial Printing Company LLC, Virgina/USA

|

CEO

... Especially in industrial postpress production for digital printing, stability, accuracy, and service quality are essential — and Hohner has consistently delivered all of these for years. I value the well-engineered machine design, the outstanding build quality, and the fast, practical customer support. Hohner’s systems are designed to integrate seamlessly into modern digital print workflows, which is a true advantage for high-volume production environments like ours. Hohner combines traditional German engineering excellence with modern digital integration. What truly sets them apart is their exceptional customer support: rather than supplying machines, Hohner partners with their customers by providing deep technical expertise, short response times, and a genuine interest in the success of each application. This level of partnership is rare in the market and represents a significant added value for us."

Hervé Lesseur,

TagG Informatique

|

CEO

... Forget the mass campaigns with several hundred thousand recipients but also the waves of e-mailings - certainly quite economic but often with the riskiest fallout. We are now entering a period of maturation where each technique naturally finds its place. Thus, today, at TagG we print and customize starting from the blank sheet with total variability, it is the CMYK customization. To go even further, by using the know-how of our internal Research and Development team, we developed Ultraflex: The customization that allows the adaptation to your requirements: format, paper, content, images... for truly unique messages. At TagG, more than ever, innovation and creativity dictate our daily lives. The decision to choose the new Hohner HHS-FUTURA Hybrid Finisher, which will be installed in spring 2022, is perfectly in line with our philosophy. In addition, Hohner's experience in the world of industrial saddle stitching, the robustness of the equipment, the ease of its use and the way in which it can adapt to the different needs of the market have enhanced our choice significantly."

Takashi Yanagawa,

FFGS/Fuji Film

|

... Hohner perfectly fits in our strategy and product portfolio as they demonstrate a great flexibility and willingness to adapt and customize machines to our needs. We have immediately noticed the very high technology behind their engineering and have considered Hohner saddle stitchers and DIGI-Finishers to be attractive for us and the Japanese market. The partnership with Hohner works well, because they are really interested to understand the particular requirements of our market. In terms of Management the shows the right personality; but really, the whole team proves flexibility and speed on demand with a serious attitude of continuous improvement. We look forward to growing this partnership further to a successful business in Japan for a long future in our mutual interest."

Bo Zhu,

Zhejiang Lanbao Machinery Co.,Ltd

|

Managing Director

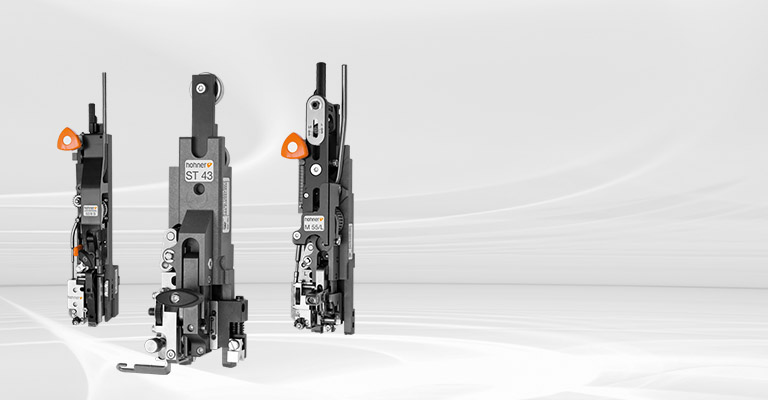

... about the higher price level of the Hohner stitching heads. So we have followed the smart proposal of Hohner Nanjing to go for a test phase with Hohner heads at one of our final customers with the result that all of us have been convinced of the extraordinary quality of Hohner’s stitching heads; with 10 stitching heads per machine it’s evident that a defect head causes a production stop each time, which means a high cost for our customers. In the meantime we equip all our machines with hundreds of the reliable Hohner stitching heads 43/6 and 52/8 per year and in this way help our customers to save money. Hohner to us means definitely quality that pays off.“

Zhenmin Dong,

Tianjin Shiwei

|

Plant manager

... which should match our expectations towards speed, product variety, flexibility and fast customer service and granting next to that the highest technological reliability. The DIGI-Finisher fulfils all that; it has been the perfect decision for us; the fact of having right a year later another second line of the same type, is probably the best proof.“